Hello, well-wishers!! It’s me, AFIF AL TAMIM. Today I will discuss the process of making bamboo fiber fabric. Stay tuned.

Bamboo fiber fabric is made in a process where bamboo stalks are converted into soft, durable, and eco-friendly textiles. There are two primary methods for making bamboo fiber fabric, namely mechanical and chemical.

Mechanical process:

This process is also called “Bamboo linen.” Firstly, bamboo branches are cut into small pieces. The pieces are crushed and mixed with natural enzymes, which break down the bamboo cell walls and help to release the fibers. After being spun into yarn, the bamboo fibers are weaved into fabric. The process is quite environmentally friendly. This process requires more labor and is used less as the cost of production is higher.

Chemical process:

This process is also called “Bamboo rayon.”. Firstly, the bamboo stalks are collected and cut into pieces in a mechanical process. The pieces are soaked in a strong chemical solution. Commonly, sodium hydroxide and carbon disulfide are used. They dissolve cellulose. The viscous liquid is then pushed through a spinneret into a solid fiber. These fibers are washed and spun into yarn. This fabric is soft, breathable, and has a silky texture. This process is less eco-friendly due to the use of chemicals.

Advantages of bamboo fiber fabric:

- Softness and Comfort: Bamboo fabric is incredibly soft and smooth, often compared to the feel of silk or cotton. This makes it comfortable to wear and ideal for clothing, bedding, and other textiles that come into contact with the skin.

- Breathability: Bamboo fibers have excellent breathability, allowing air to flow through the fabric and helping regulate body temperature. This makes bamboo fabric especially good for warm-weather clothing and activewear, as it helps keep the wearer cool and dry.

- Moisture-Wicking: Bamboo fabric is highly absorbent and has moisture-wicking properties, making it effective at drawing sweat away from the skin and keeping the wearer dry. This makes it ideal for activewear, towels, and undergarments.

- Antibacterial and Hypoallergenic: Bamboo has natural antibacterial properties that can help reduce odor and bacteria buildup. This makes bamboo fabric a great option for people with sensitive skin or those prone to allergies, as it is naturally hypoallergenic.

- Eco-Friendly: Bamboo is a highly sustainable and fast-growing plant that requires minimal water, pesticides, or fertilizers to grow. Using bamboo for fabric helps reduce the environmental impact compared to more resource-intensive crops like cotton. Additionally, bamboo fabric is biodegradable, making it an eco-friendly choice.

- UV Protection: Bamboo fabric provides some natural protection against harmful UV rays, offering a level of sun protection for the wearer.

- Durability: Despite being soft, bamboo fabric is strong and durable, meaning it can withstand frequent washing and wear without losing its integrity or softness.

- Thermal Regulation: Bamboo fabric has natural insulating properties, keeping you warm in cooler weather and cool in warmer conditions. This makes it versatile for year-round use.

- Breathable and Odor-Resistant: Bamboo fabric is naturally resistant to odors, thanks to its antibacterial properties. It helps to keep clothing and other textiles fresh for longer, reducing the need for frequent washing.

Disadvantages of bamboo fiber fabric:

- Chemical Processing: Although bamboo is a sustainable and eco-friendly material, the process of converting bamboo into fabric (especially rayon or viscose) often involves the use of harsh chemicals, such as sodium hydroxide and carbon disulfide. These chemicals can be harmful to the environment and workers if not properly managed.

- Durability Issues with Some Fabrics: Bamboo fabric, especially when processed into rayon or viscose, can be less durable than other fabrics like cotton or polyester. It may be prone to pilling, fraying, or weakening over time, especially if not properly cared for.

- Expensive Production Costs: Bamboo fabric production can be more expensive than traditional fabrics due to the complex chemical processing required to turn raw bamboo into soft, wearable fabric. This can result in higher costs for the final product, making bamboo fabric less affordable for some consumers.

- Shrinking and Stretching: Bamboo fabrics, particularly those made with a chemical process, can shrink or stretch after washing. This can affect the fit and appearance of the clothing or textile items made from bamboo fibers.

- Lack of Uniformity: Bamboo fabric can sometimes lack consistency in texture, feel, and quality, especially if it’s processed with different methods. For instance, bamboo fabrics made using a mechanical method (bamboo linen) may be stiffer and less smooth compared to bamboo rayon, which has a softer feel but might not last as long.

- Environmental Impact of Processing: While bamboo as a raw material is environmentally friendly, the extensive chemical treatment required to turn it into fabric can offset some of the eco-benefits. The chemicals used in processing bamboo into rayon or viscose are often not biodegradable and can cause pollution if not managed correctly.

- Limited Knowledge of Sustainability: Despite bamboo being a fast-growing and renewable resource, consumers may not always be fully aware of the environmental impact of its transformation into fabric, especially when it comes to the use of toxic chemicals in the manufacturing process.

- Moisture Retention: Bamboo fabric is absorbent, but it may not dry as quickly as some other moisture-wicking materials, which can be a downside in certain applications like activewear or towels, especially in humid environments.

Pingback: Natural vs Synthetic Fibers-Difference-Types-Benefits 2025

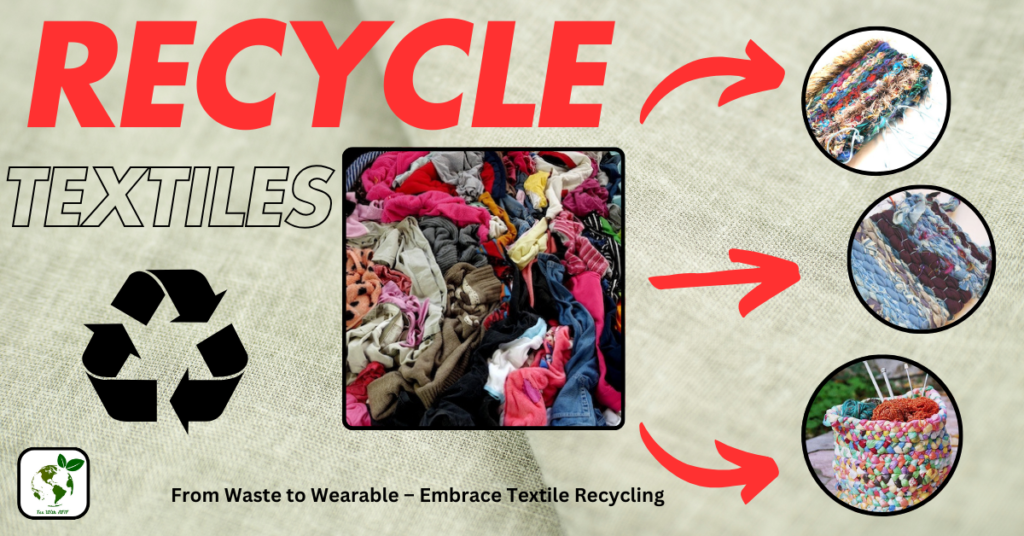

Pingback: How to recycle textiles? Recycling process of textiles 2025

Pingback: How Spider Silk is made? Process-Fiber formation 2025

Pingback: What is the Textile Industry? Definition-Sections &more-2025

Pingback: How Cotton Yarn is made? Full process in details-2025